Master CNC programming through advanced CAD/CAM software and machine simulation tools. Learn to create efficient toolpaths and generate G-code for real-world manufacturing applications.

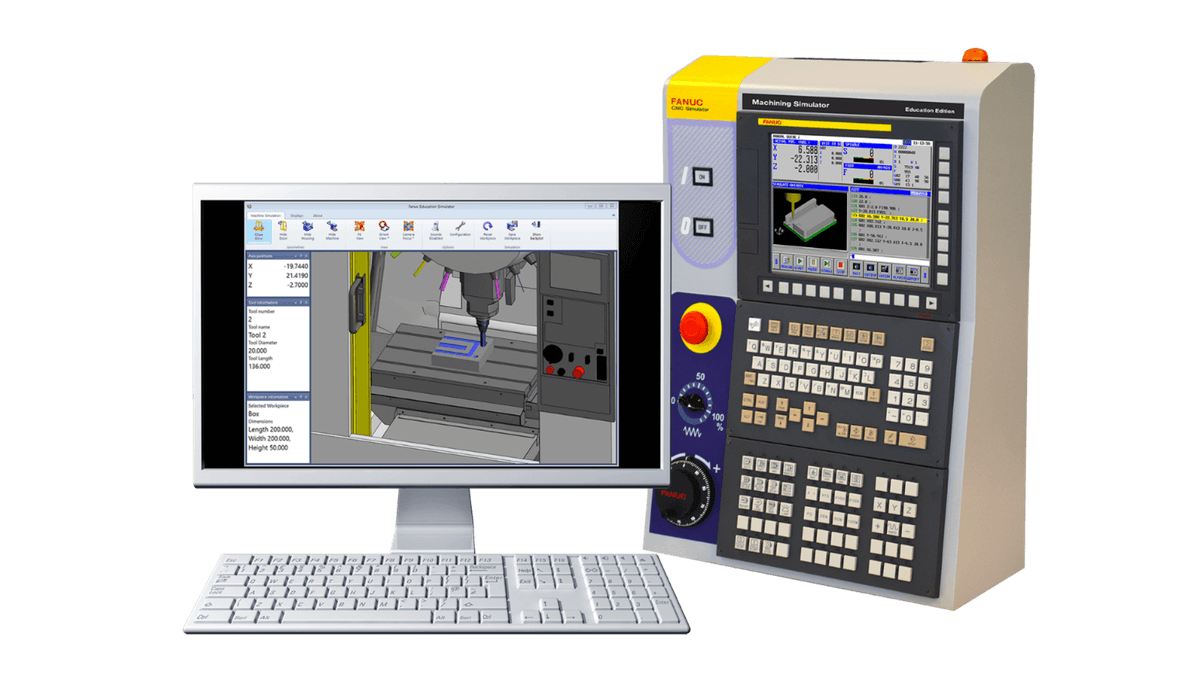

Experience powerful CNC simulation tools that allow you to program and test machining operations safely before running them on actual machines

State-of-the-art simulation software allowing students to program and operate CNC machines safely before touching real equipment

Seamless workflow from design to manufacturing with integrated CAD modeling and CAM programming capabilities

Training on professional software including Mastercam, Fusion 360, SolidWorks CAM, and NX CAM used in real manufacturing

Train on industry-leading CAD/CAM software used by professionals worldwide in manufacturing and education

Cloud-based 3D CAD, CAM, and CAE platform for product development

Comprehensive training across all types of CNC machining operations

2D/3D contour, pocket, drilling, and surface finishing

Facing, roughing, finishing, and thread cutting

4-axis and 5-axis simultaneous machining

Combined milling and turning in single setup

CNC programming skills open doors across diverse manufacturing industries

Precision parts, turbine components

Engine blocks, transmission parts

Surgical instruments, implants

Injection molds, stamping dies

Housings, heat sinks, connectors

Turbine blades, valve components

Everything you need to know about our Drone Lab programs

CNC simulation allows safe, cost-effective learning without material waste or machine damage. Students can practice complex operations, test programs, and make mistakes in a virtual environment before working on real machines.

Students learn G-code programming, M-codes, macro programming, and various CAM software packages. Training covers both manual programming and computer-assisted programming techniques.

Yes, the curriculum includes real-world projects simulating actual manufacturing scenarios. Students work on parts from automotive, aerospace, and medical device industries to gain practical experience.

Graduates can pursue careers as CNC programmers, machine operators, manufacturing engineers, quality inspectors, and production supervisors in precision manufacturing industries.

Join our comprehensive 3D printing program and master the technologies that are revolutionizing manufacturing.